PFAS treatment

For many, the treatment of PFAS is a big challenge due to the scope of the pollution. Aquarden believes in onsite and sustainable treatment of PFAS along with its complete destruction with SCWO to provide a safer environment for future generations. Below is a description of what we find to be the best available technique for capturing and destroying PFAS.

About PFAS pollution

Being a highly persistent substance, PFAS is very resistant to traditional techniques like biological treatment. Even more aggressive chemical oxidation methods such as ozone or Fenton’s oxidation are typically inadequate to completely breakdown PFAS to non-toxic byproducts. When it comes to onsite PFAS treatment, most conventional technologies are merely preventative, where PFAS is typically isolated but not destroyed.

It is important to be aware that PFAS treatment includes two processes:

1: PFAS capture

2: PFAS destruction

At many pollution sites, PFAS contaminated material such as polluted soils and spent adsorbents are either directly deposited in landfills or sent for incineration. Aquarden Technologies does not consider landfilling of PFAS contaminated material a proper solution as it simply delays the problem – rainwater precipitation on the landfills generates PFAS-contaminated leachate that simply returns into our environment. The fate of PFAS with incineration is also largely undocumented, where toxic byproducts may accumulate in incineration ash or spread into our atmosphere from smokestacks due to incomplete destruction.

PFAS Capture

A range of commercially available methods exist today that are effective at capturing and isolating PFAS from contaminated water or wastewater collected from washing of contaminated soils.

Our White Paper “How to Capture and Destroy PFAS” accounts for the different techniques and their respective challenges.

PFAS treatment train

Aquarden has experience designing treatment trains for the capture and destruction of PFAS that are customized to the wastewater composition. One method which has proved very efficient even for high water flows is based on ion-exchange resins (IER) to capture PFAS. Certain IER are highly PFAS-selective and can capture very high loads of PFAS before saturation while also capturing both short and long chain PFAS. To capture PFAS, wastewater typically pass through one or more modular adsorption columns.

The first adsorption column is efficient at removing organic material but has a low PFAS selectivity and lets PFAS through. The second adsorption column contains ion exchange resins (IER) which are highly PFAS-selective and removes PFAS below detection limits. However, IER is highly sensitive to the presence of other organics and minerals in the wastewater that can foul the IER and reduce its ability to capture PFAS. To ensure optimal performance of the PFAS adsorption columns, it is important that additional pre-treatment processes are utilized to first remove other minerals and organic compounds that may interfere or compete with the PFAS adsorption process. Upon saturation with PFAS, the spent adsorbent is replaced with fresh adsorbent, while the PFAS-saturated adsorbent is sent to our SCWO plant for complete destruction.

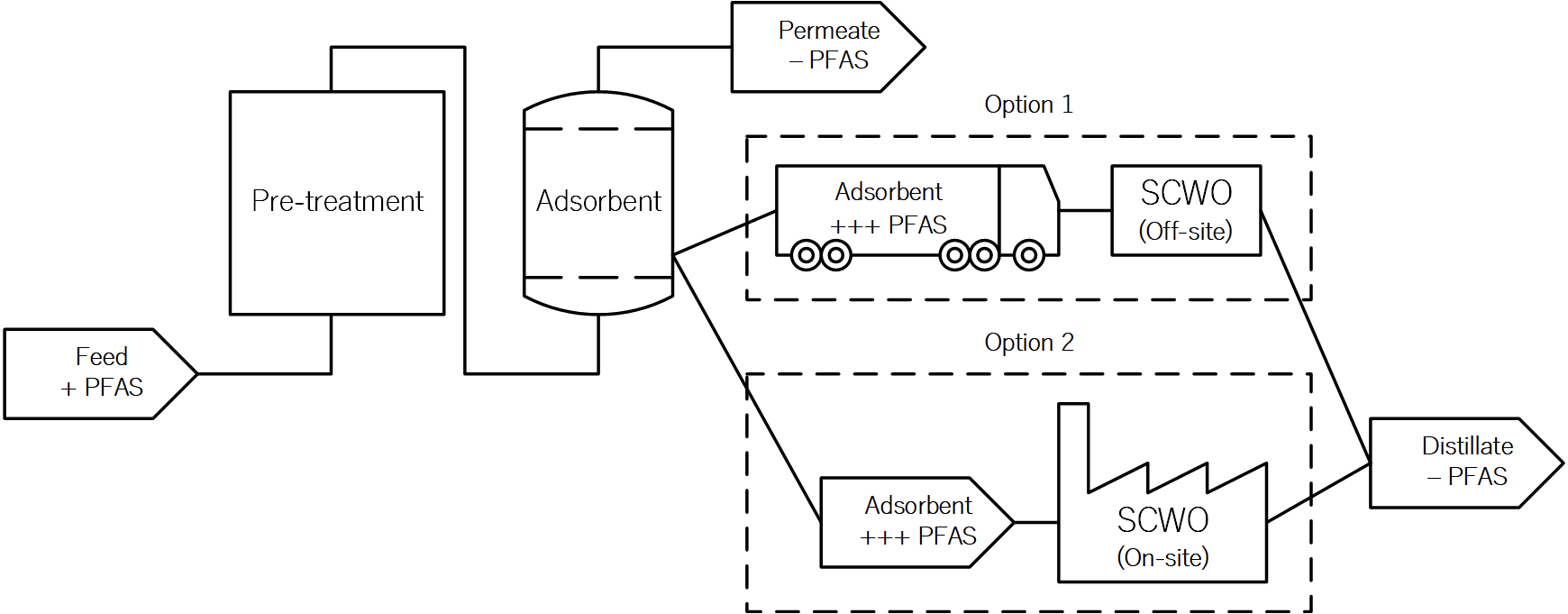

The diagram below illustrates the complete process:

Example SCWO-adsorption process for PFAS treatment

Left: Aquarden containerized PFAS pre-treatment plant comprising chemical flocculation and microfiltration. Right: Pond polluted with PFAS from firefighting activities. Note the green algae plume that can interfere with the PFAS adsorption process if not properly removed by pre-treatment systems.

The superior PFAS-destruction efficiency of SuperOx® SCWO is described here: technical explanation and key benefits.

Other PFAS capturing methods might be chosen depending on the water composition, flowrate, and complexity, such as foam fractionation.

PFAS Destruction

Aquarden believes SCWO and subCWO to be current best available technologies for PFAS destruction, as it can ensure destruction with minimal emissions of toxic byproducts to our environment due to the water-based treatment process. When working with very highly concentrated PFAS wastes like firefighting foam (AFFF) containing > 1g/L PFAS, trace amounts of PFAS may still be detected despite a 99,99% PFAS destruction efficiency from SCWO treatment.

However, the advantage of SCWO and subCWO is that the entire process is water-based, meaning any remaining PFAS are contained in a water phase that can simply be polished with resins to below detection limits and retreated with SCWO. All treated water can be safely analyzed prior to discharge, unlike with incineration where any unwanted emissions are immediate into our atmosphere.

Incineration remains largely undocumented with regards to its PFAS destruction efficiency, where PFAS may be emitted through smokestacks or accumulate in incineration ash due to inadequate operating temperatures and residence times. Many PFAS require extremely high temperatures typically above 1000 oC, with some fluorinated compounds requiring temperatures over 1400 oC for complete destruction.