“At Aquarden we believe all our planet’s man-made water problems can be solved sustainably today.”

Supercritical Water Oxidation with SuperOx®

Our unique and prize-winning SCWO system – SuperOx® – is specifically designed for treatment of wastewater containing toxic and hardly-degradable organic compounds.

- Environment-friendly system with complete elimination of organic pollutants

- One-step removal of organics, salts, and heavy metals.

- No toxic by-products

- Fully automated system

- Reuse of energy and water

What we do

Consultancy

- Total solution design

- Laboratory test and pilot tests

- Cost/benefit analysis

- Environmental approvals

System & solutions

- Production of turnkey SCWO solutions

- Pre and post-treatment systems

- System integration

Service & support

- SCWO treatment onsite or at local treatment stations

- Operation and monitoring of wastewater treatment

- Flexible service and support packages

- Maintenance

Industries we serve

PFAS & Micropollutants

Destruction of toxic micropollutants such as PFAS and pesticides.

Chemical

Destroying organic compounds and surfactants.

Pharmaceutical & biotech

Dealing with toxic and hardly-degradable API’s.

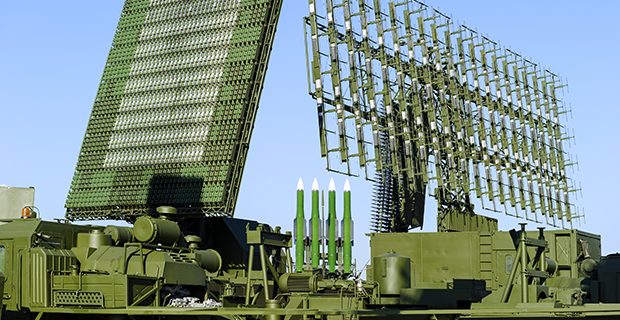

Defense industry

Operating in the fields of energetic wastes and chemical warfare

About

Innovation in cleantech solutions

Aquarden was founded in 2005 inspired by the results of an EU-funded research project demonstrating the remarkable performance of SCWO for the treatment of wastewater.

Since then Aquarden has progressed continuously towards commercializing its SCWO system, which received the European Business Award for the Environment in Denmark in 2016 for its significant contribution to a sustainable development and innovation.